articles/Monitors/xritei1profiler-page3

X-Rite i1 Profiler Suites - part 3 of 1 2 3

by Mike McNamee Published 01/06/2011

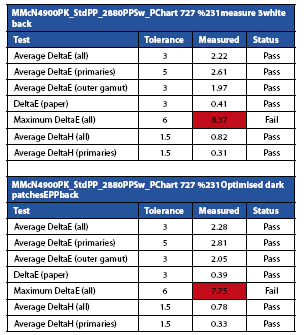

The effect of the additional patches has not dragged the audit result into specification and we need to do more work to fully understand the workings of this feature.

By now you have successfully, and easily, made your first profile. We made and audited some test prints which were visually impeccable, certainly good enough for even the highest class of commercial or social printing. The requirements for contract proofing and high-precision work are more demanding and, for this, additional facilities are provided (see later).

At a simpler level, and for the 'photo' versions, a Macbeth ColorChecker is provided. This has holes punched into each patch so that a test chart may be printed and the reference chart placed on top. The decision as to whether the test print matches the reference chart is an arm-waving exercise which has no real place in precision work - we need numbers! It is a fair assumption that the resulting print will be so good that you cannot discern any variations using this visual method and so, at best, it will only filter out complete goofs in the profile build (yes they do happen!). There are differences in the shine between the matte target and gloss or lustre papers which have a greater influence on judging of the dark tones than anything else. Suffice to say that our first profile build was so good that the 'holy' Macbeth Chart provided only a token confirmation of the print accuracy.

CMYK Profiling

The workflow is essentially the same for profiling for CMYK devices (and RIPs) except that more sophistication is provided. To start with, CMYK targets are always larger and 17 industry targets are provided as defaults, along with the ability to make a target between 400 and 6,000 patches. Prelinearisation is also required either via the RIP software or through i1 Publish.

The QA facility is also better for CMYK profiles and either the GRACol IDEAlliance target or the Fogra Ugra Version 3 test patch sets are provided. These are a compromise between speed and accuracy, and patch sets of around 72 are the chosen compromise. At Professional Imagemaker we boost the CMYK-based 72 patch set with additional skin tones, Macbeth sets, greys and our HIGam patch set, to provide more coverage than is normal from a CMYK press. However, the built-in set that comes with the software is very quick and very easy to use. Here again the tolerance of patch size and spacing was a benefit, we used the available 8mm target instead of the default 10mm and the spectro measured it without a murmur!

The print QA feature is primarily intend for CMYK workflows but does a fast and efficient check on RGB outputs as well. This feature alone, we consider to be worth the cost of an upgrade!

We audited our RGB profiles using the CMYK targets as this provides a numerical report on the accuracy of the output. We first re-ran a GMG certified-print to test the system. This reported the near-perfect errors expected, confirming the measurement system. The as-made print produced an error of 2.18 ?E Lab and the audit would have passed Fogra contract proof certification grade other than a trio of seemingly unrelated patch errors which just breached the limit of 6 ?ELab in two instances and 8.72?ELab as the worst value. This is really good shooting as unprofiled printers often record average value of 10 to 15 ?ELab.

It seemed to be a candidate for using a second iteration of the profile. A number of options are available and we first tried to add another 400 patches to the test set and reprofiled. This had a minimal effect on the error values. Next we used the Pantone patch set generator to compile a bespoke test set of tones, close to the errant values. This too had a minimal effect on the outcome of the audit. It swapped the errant, outof-specification patches, but replaced them with two others of higher than7?E Lab errors.

For the present, this is as far as we need to go and we are waiting the arrival of RIP software to continue more in-depth testing. The overall impression is that the software is simple to use, creating profiles of a quality which is equal to that created by Monaco Profiler Platinum but, as yet, not exceeding it. The limitation might be the RGB printing system and the linearisation facilities provided by a typical RIP might be needed to get us into compliance with Forga-certified standards. In many ways it is frustrating to be so close but just outside the specification. Psychologically there is a world of difference between saying 'this print complies' and having to finesse any queries with caveats such as 'it's only just outside specification'. However, it is early days yet and packages of this sophistication often require a little time to 'bed down' before you can extract every last ounce from them. We can confirm so far that we have made an excellent start and the new software is very simple to use. The optimisation has failed to impress so far, the refined profiles are creating proofs which are visibly indistinguishable from each other but the statistics need to comply before you can put a stamp on the print! A little more work is needed and we will report in due course, along with our experience using the software to profile monitors and projectors.

Please Note:

There is more than one page for this Article.

You are currently on page 3 Contact Mike McNamee

1st Published 01/06/2011

last update 21/07/2022 08:46:27

More Monitors Articles

There are 0 days to get ready for The Society of Photographers Convention and Trade Show at The Novotel London West, Hammersmith ...

which starts on Wednesday 14th January 2026